Challenges and Bottlenecks in Highway Maintenance

Currently, the lifespan of asphalt pavement on highways is generally around 15 years. Pavements are susceptible to climate impacts: softening under high temperatures, cracking in cold conditions, and water damage in humid environments, significantly compromising durability. As a result, road inspections, disease identification, and timely repairs are critical. Traditional maintenance methods rely heavily on manual inspections, conducted either on foot or at low speeds in emergency lanes, which pose several issues:

Low Efficiency: Time-consuming inspections with limited coverage.

Restricted Perspectives: Blind spots hinder thorough monitoring of high-risk areas like slopes and bridges.

Safety Risks: Inspectors face hazards while working on highways.

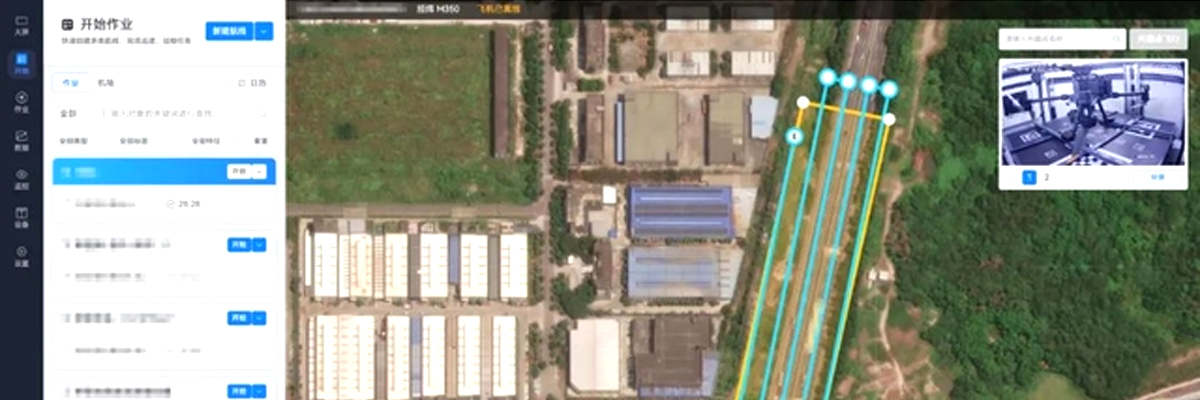

Fully Autonomous Flight Algorithms + AI Recognition for Precision Maintenance

To address the pain points of traditional highway maintenance, Fuya Intelligent's drone autonomous flight system integrates core technologies such as flight algorithms, AI image recognition, and automated drone stations. This enables end-to-end intelligent inspection upgrades, offering innovative solutions for precision highway maintenance.

Comprehensive, Blind-Spot-Free Inspections

Compared to manual inspections, drones provide broader perspectives, excelling in slope monitoring. They access complex terrain to capture 4K high-definition imagery, accurately assessing slope stability and detecting risks like slippage or cracks. Additionally, drones conduct full-coverage inspections of critical sections, including road markings, guardrails, and drainage systems, eliminating oversight.

3D Modeling and Data Visualization

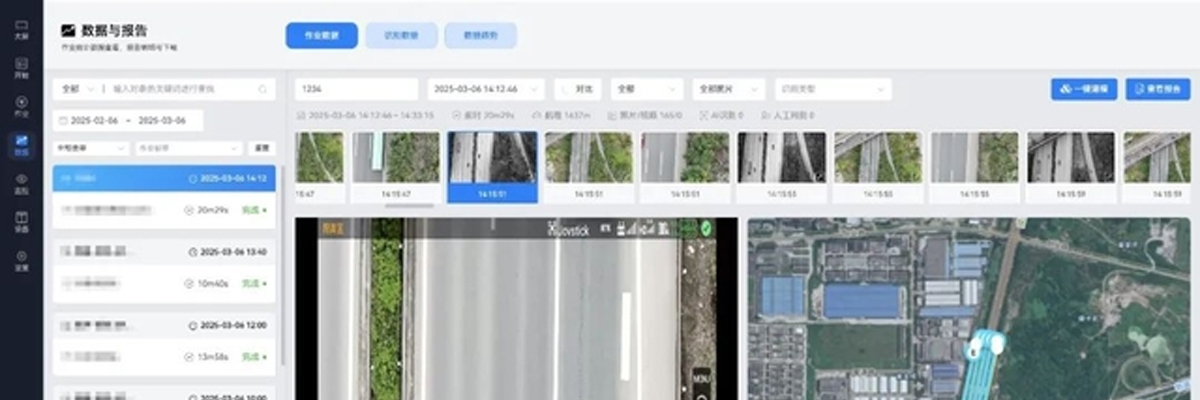

Traditional methods rely on 2D blueprints, while Fuya Intelligent's drone system rapidly generates 3D models, creating a more intuitive and precise disease monitoring framework. Through the Ruiyun control platform, managers can view real-time road conditions, analyze disease trends, and develop data-driven maintenance plans.

Accurate and Efficient Disease Identification

AI algorithms automatically identify pavement defects. High-resolution cameras collect data for real-time cloud-based analysis, detecting cracks exceeding 5mm, potholes, and other issues. The system pinpoints locations and triggers immediate alerts, enabling rapid intervention to shorten repair cycles.

Bridge and Road Construction Supervision

Bridge structural safety-especially for cross-river bridges-is a key focus. Traditional inspections struggle with environmental constraints, while drones perform regular structural checks and track disease progression. They also enable high-frequency remote monitoring of road construction sites to ensure safety compliance.

Smart Data Management and Decision Support

Inspection data is transmitted to the cloud platform in real time, where it is automatically categorized to build a highway disease database. Leveraging AI analysis and data mining, managers can quickly retrieve historical records, predict disease trends, and optimize maintenance strategies.

As highway networks expand, traditional maintenance models are transitioning toward intelligence. Autonomous drone inspection systems, with their efficiency, safety, and precision, are revolutionizing highway upkeep. With ongoing advancements in AI recognition, drone technology, and automated data management, the future of smart highway maintenance promises even greater sustainability and intelligence.

Post time: Mar-18-2025